Blizzard-Tecnica, a division of the Italian Tecnica Group S.P.A., launched a revolutionary ski boot recycling initiative in Europe in autumn 2021 called “RecycleYourBoots,” short ‘RYB’. More than just a lip-service promise to recycle, the division of the Italian ski and boot manufacturer actually devised an entire end-to-end project from collection, transport, and breaking down of materials to reusing the recycled raw materials in their own production. In the first year of the RecycleYourBoots RYB program, more than 4,200 ski boots were collected from 54 retailers in seven European countries. This year 150 retailers are involved, including online retailers and rental shops that will be included in the RYB program. The goal is to reach 20,000 recycled ski boots by the end of the third year, also involving the Nordica brand.

The Tecnica Group is based in the Italian province of Treviso, which is about 45 minutes from Venice, Italy. Founded in 1960 by Giancarlo Zanatta as a work boot manufacturer, the company expanded over time into the sports market, both organically as well as through a series of strategic acquisitions. The company invented the world-famous 80s snow boot the ‘Moon Boot’. In 2003 Tecnica purchased Rollerblade, the leader in inline skating. In 2006 Tecnica bought the majority of shares in Austrian ski manufacturer Blizzard Sport GmbH and consolidated the Blizzard manufacturing with its ski manufacturer Nordica, making it one of the largest ski gear manufacturers in the world. The combined company had a revenue of roughly €466 million in 2021. The founder’s son, Alberto Zanatta, is the President of the Tecnica Group and is also the Director of the Board of Directors.

Plastics stay in the environment for thousands of years before decomposing. Plastic waste is growing exponentially as it typically ends up in landfills. As an alternative, plastics can be burned, but the process releases harmful chemicals. 99% of all plastic is made from chemicals sourced from fossil fuels, thus contributing to CO2 emission. Plastic recycling only accounts for about 9% of all plastic waste. Plastic recycling can reduce pollution and CO2 emissions. Unfortunately, often plastics collected for recycling end up in landfills or, even worse, our oceans. Blizzard-Tecnica wants to do more than its share to improve this situation.

Alberto Zanatta is an avid skier and the recycling project is a matter very close to his heart. He stresses about the RYB program: “We are not simply creating and selling a product, but setting up a fully-integrated sustainable process: production, transport, recycling, and consumption.” The RYB program has seen its first successful winter season in Europe and Zanatta is keen to find a recycling partner in North America. He acknowledges the importance sustainability carries in the US and Canada, saying: “Consumers there have sustainability inside, for them the playground is nature.”

Project Partners

For this project, Tecnica sought several strategic partners:

- University of Padua, Italy, one of the oldest universities in the world, was brought in as a partner to more accurately measure the impact the ski boot industry created, as well as devising a plan to reduce this impact and measuring its success.

- LaPrima Plastics, Italy, is the recycling partner for the project. LaPrima is based in the province of Vicenza, less than an hour from Tecnica headquarters, and specializes in the recycling of plastics. The company creates plastic granules out of old plastic that can be reused in industrial production of goods. LaPrima processes more than 8,000 metric tons of industrial recycling a year.

- Fecam Srl specializes in automated production in the footwear sector and produces parts for ski boots and skates, including metal and carbon parts. The company is very committed to the world of recycling and has developed a process for breaking down old ski boots into 120 separate components.

- InterSport is a union of independently owned sporting goods retailers in Europe with headquarters in Bern, Switzerland. The network of retailers was brought in as partners to help facilitate the collection of old ski boots. In the first instance, the list of companies from which to collect old ski boots included Italy, France, Switzerland, Austria, Germany, Norway, and Sweden. The collection points will be expanded to include Great Britain, Belgium, Holland and the Czech Republic.

- Fercam, Italy, is the transport partner that aims to minimize distance traveled by optimizing collection routes. Ski boots are collected in minimum batches of 25 to reduce emissions. Fercam has a fleet of reduced environmental impact vehicles such as LNG trucks and electric vans for the last mile sections. Fercom has adopted specific CO2 emissions accounting, neutralization, and offsetting measures for the shipments.

- LiSki, Italy, is a manufacturer of protective mattresses on ski fields globally. Together with ReMat and Tecnica, a new, thinner mattress was designed that consists partly of recycled liners from the RYB project. Crash tests have shown that the new recycled mattress, which will be adopted to protect the most important Italian ski resorts and in the world, responds just as the older, thicker mattress did.

- The project is also supported by the Federation of the European Sporting Goods Industry (FESI) and the Museo Dello Scarpone e Della Calzatura Sportiva (Museum of ski boot and sports shoes) in Montebelluna, a region in Northern Italy famous for sport shoe production.

How to participate?

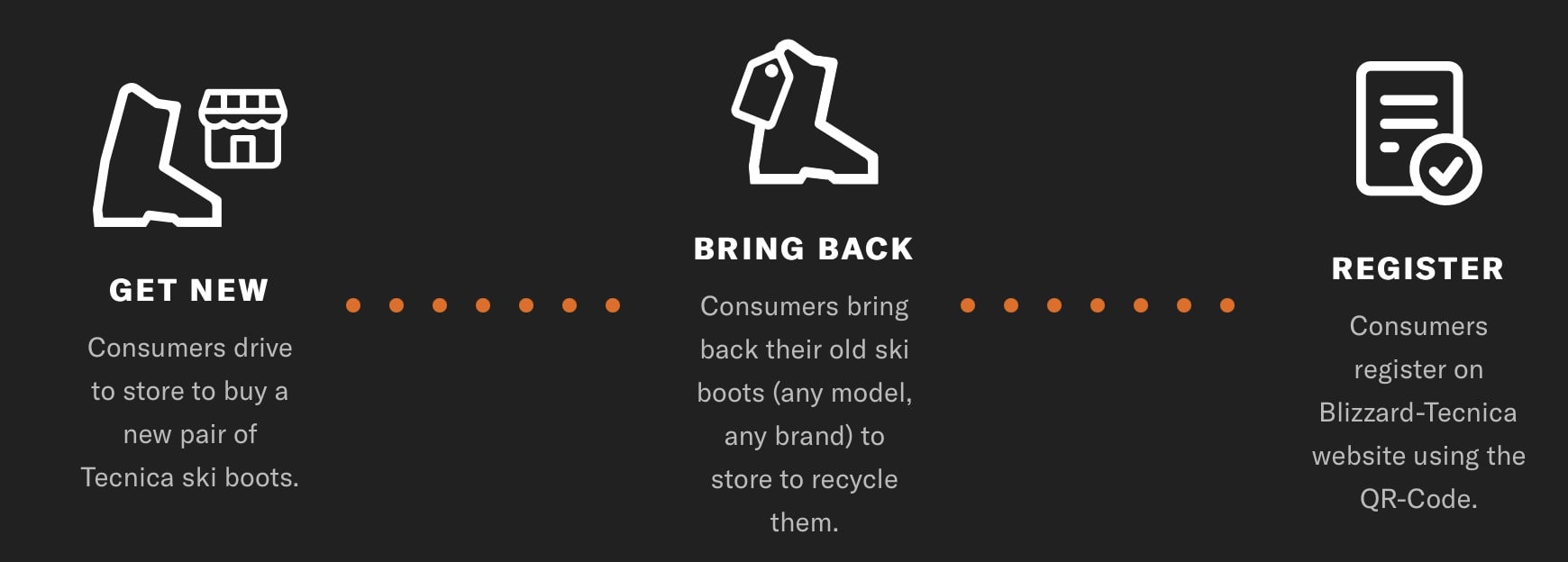

Tecnica wants to offer buyers of a new Tecnica ski boot the opportunity to fully recycle their old ski boot regardless of the brand. You can find participating RYB retailers on the store locator. There you can take your old boots — of any brand — when you buy a new Tecnica boot. Register with a QR code on the Blizzard-Tecnica Website for the project. If you are buying online, you will receive instructions from the online retailer when you receive your new ski boots. You can use the Tecnica box your new boots came in for free shipping of your old boots. Tecnica also is committed to picking up all old rental ski boots at the end of their lifespan from rental shops and has added rental shops to the program for the upcoming season.

How does it work?

Old ski boots are collected in batches at retailers and delivered to Fecam, who break the boots up into its original components. Ski boots consist of 120 components, 70 of which are in the liner. First the inner boot is removed. Then each boot is dismantled to separate all components, for example, buckles are removed, screws from the soles removed, etc. Then the individual components will be transported to the nearby LaPrima Plastics plant for recycling.

How is it recycled?

Metals have been sorted into ferrous and non-ferrous materials and can be remelted into new buckles for ski boots but can also be used in bicycle frames, building materials, and canned drinks. Aluminum is infinitely recyclable and recycling requires only 5% of the energy of producing primary aluminum, thus reducing CO2 emissions. Plastics were separated into Thermoplastic Polyurethane (TPU) and Polypropylene (PP). Polypropylene can be turned into small granules which can be remelted and used for example in the manufacture of plastic chairs, flooring, and containers. TPU can be reused in new ski boots, for example in soles, inserts, reinforcements, and wedges. The lining was posing the most difficult to recycle, but thanks to a collaboration with ReMat this year, they found a way to turn the shredded liners into a compact sheet of regenerated material, which new partner LiSki will turn into the padding of protective mattresses. Tecnica will also use recycled materials in its new ski boots as the company is committed to closing the loop of this circular economy. Tecnica furthermore is redesigning its ski boots in a more ecological way. At the moment, up to 30% recycled materials can be used in a new ski boot by Tecnica.

“We hope to involve skiers who want to contribute with us to reducing the environmental footprint of the skiing world,” Zanatta said in an interview with the local Italian newspaper La Tribuna di Treviso. The company will release its first sustainability report soon, which will detail all of the company’s efforts with regard to sustainability. The RecycleYourBoots program is just one part of the company’s overall efforts.

“It’s easy to get tricked into thinking that nothing we do as persons will make a change. That’s wrong. We, as skiers and end consumers, must do our best to defend and preserve the world we are connected to. Our industry is the ski industry, and we are going to start here,” the Italian company stresses.

If you love skiing, you have to invariably consider your footprint on the environment. So maybe, when you buy a new ski boot this or next season, consider the RecycleYourBoot initiative by Tecnica. It certainly makes me reconsider which brand I am buying in the coming season!