I’m pretty sure if you ask any skier the one thing they dislike about the sport, the resounding answer would be ‘the boots and the fitting process’. Professional boot fitting can take hours; trying on several pairs of boots, assuming the ski position, flexing, sitting in pain with numb feet, describing that pain to the fitter, and finally handing over 100’s of dollars. Then the fun starts, breaking in your new boots, blisters, hotspots, pinching and numerous revisits to your fitter.

Well, Fischer reckons they’ve cracked it. How about purchasing a pair of boots, perfectly fitting and uniquely adapted to fit your own personal foot shape, without needing to go through the torturous fitting process. Sound like a dream come true?

Fischer has been developing their vacuum boot since 2004. The original intent was to create shell plastics that wouldn’t respond to temperature changes, which by in large they’ve accomplished.

The latest innovation to improve their technology just won Gold in the ISPO Ski Product of the Year Award. The process is described as:

VACUUM – the next step to perfection. Maximum individuality and uncompromisingly efficient, with an eye to perfection – this is VACUUM. The interplay of three top technologies raises boot fitting to a new level and is unique in achieving a perfect fit.

Below are the three easy steps to the perfect fitting boot:

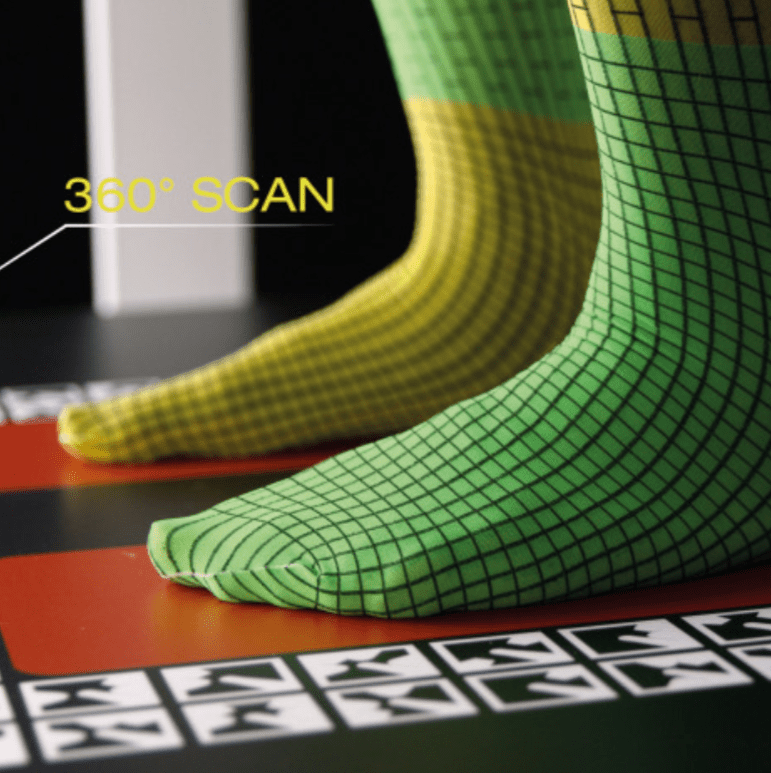

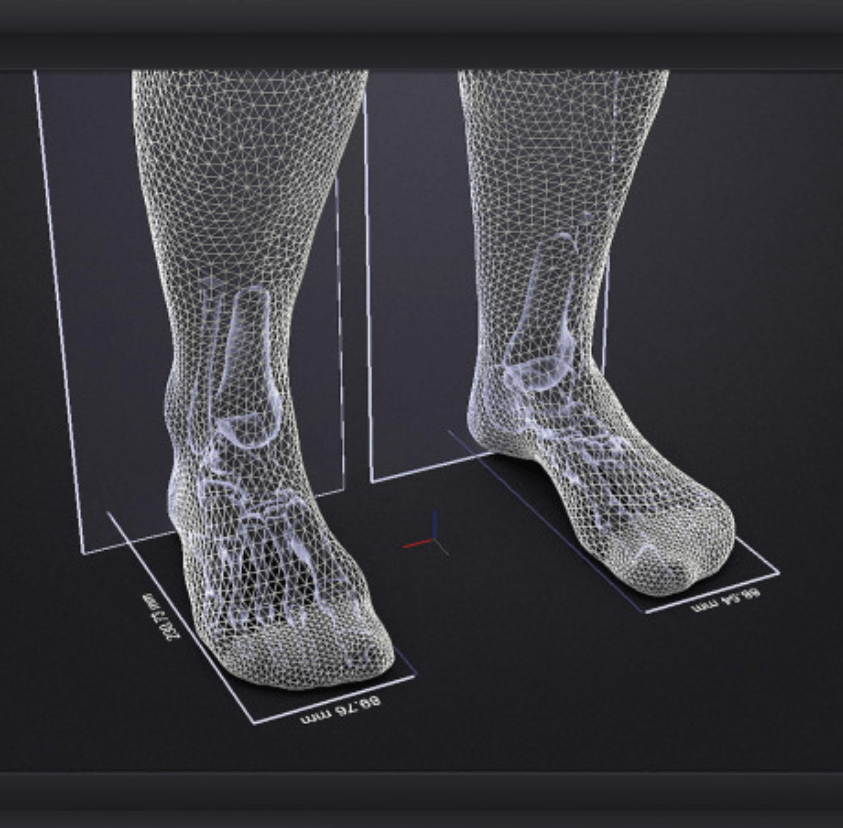

Vacuum 3D Foot Scan

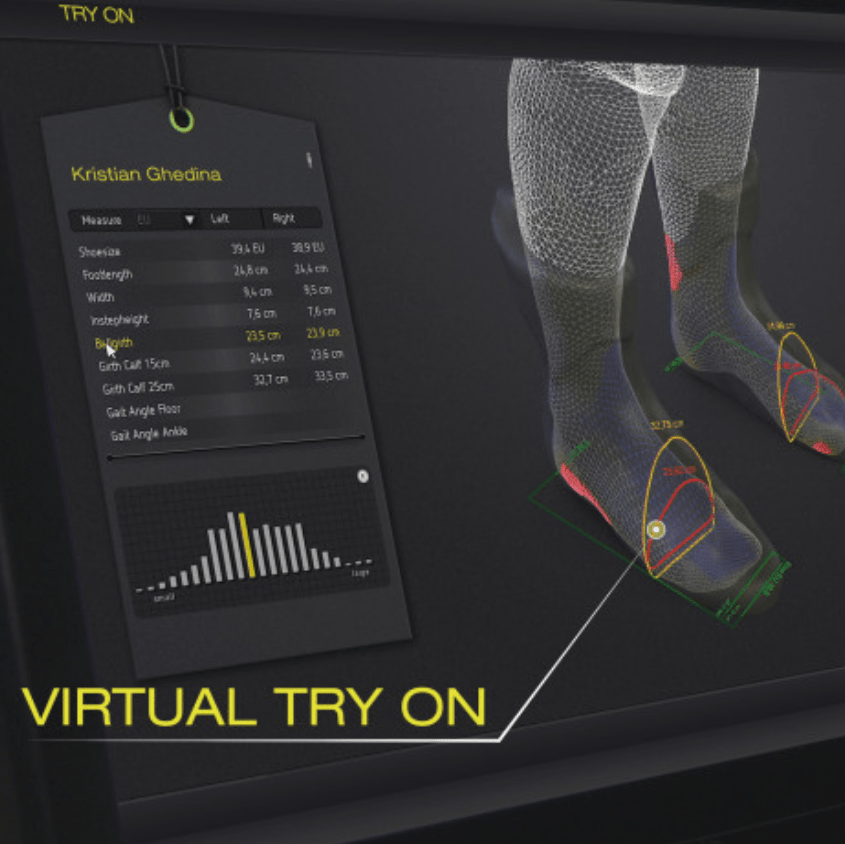

To guarantee maximum individuality when determining the right ski boot, an exact 3D scan of the feet is carried out. This means that not only the length and width but also the complete shape of the foot is precisely determined. An appropriate choice of the right boots can be made based on this analysis. In the Virtual Try-on, the boot is then placed over the scan. Any potential pressure points are identified and visualized. Should a modification be required, one of the two fitting technologies VACUUM ZONE FIT or VACUUM FULL FIT is chosen.

Vacuum Zone Fit

VACUUM ZONE FIT enables an uncompromisingly exact fitting of the shell to the individual anatomy of the foot – in exactly those places where it is necessary. First, the pressure points determined in the 3D scan are identified and analyzed. In the forming process, silicone pads are placed on the shell and the Heating Pads are activated. There is then a partial customization of the shell to the individual foot shape to achieve the optimum fit.

Vacuum Full Fit Process

VACUUM FULL FIT enables a complete fitting of the shell through VACUUM 2Zone for maximum individuality and optimum fit. In Fischer’s VACUUM FULL FIT process, the shell is heated to 80°C before you step inside the shell with the boot liner. The Cooling and Compression Pad is put on and the standing position is fixed. Fischer has developed the VACUUM Station, especially for this purpose. It is the heart of the fitting process. Compressed air is used to shape the entire boot ideally to match the foot – and the boot retains this shape once it has cooled down.

What do you reckon? I know plenty of skiers who love their Fischer boots, but would this new process influence your next boot purchase?

Would love to buy some bit where can we find a list of stockists? Going to Avoriaz in France this weekend and then based near Cannes.

Any idea where one of these machines is in the United States?

Do you have any idea where there is one of these fischer 3d boot fitting machines?