Since the 2024 snow season ended, the Perisher maintenance team has been hard at work removing the Mount Perisher Triple Bottom drive-station, making way for construction to start on the bottom station. The team will now focus on works higher up the hill.

The biggest win so far has been Doppelmayr coming up with an innovative solution to concrete supply issues by installing its own batch plant in Jindabyne. This, along with the preparatory works done pre-season to ensure a safe access road to the top station, has been invaluable and fast-tracked the project.

Over winter, Shaun Turner, General Manager of Mount Perisher 6 construction partner Doppelmayr, had the innovative idea to create the company’s own concrete source to cut down on the risks associated with uncertain concrete supply issues. “Our crews were working long hours and into the night to keep to schedules set by concrete plants,” explains Shaun. “It wasn’t sustainable, and the time we might need concrete was often outside normal business hours, which made it hard to rely on local plants.”

The availability and reliability of concrete supply became one of the highest project risks, especially when the delays meant crews might need to wait around until the concrete arrived if the delivery times were pushed back. As a solution, Doppelmayr applied for a Development Application to produce its own concrete, which was granted. This October, Doppelmayr has made around 400 cubic metres of concrete, which has been placed on-site.

“A good example of how effective it’s been was just this week when we excavated Tower Two. By 11:00 a.m. on Monday, it was excavated. At midday, we had geotechnical approval and by 1:00 p.m. the concrete was in. This process would normally take a few days between each step. It’s making a huge difference.”

He explained the process of making concrete as like baking a cake where there are lots of different ingredients, methods and outcomes. “We use sand, aggregates, cements and fly ash, placing it all together in the truck and mixing it up to the right consistency before taking it to the site, around an hour away,” said Shaun. “We have an internal booking system so a crew could book the concrete 2-3 days out, or even as little as 1-2 hours in advance.”

It takes about an hour to create 30 cubic metres of concrete at Doppelmayr’s Jindabyne concrete plant, and another hour to transport it to the Perisher site. A Development Approval has been presented for a Smiggins concrete plant to make it even quicker to turnaround concrete for the Mount Perisher 6 project.

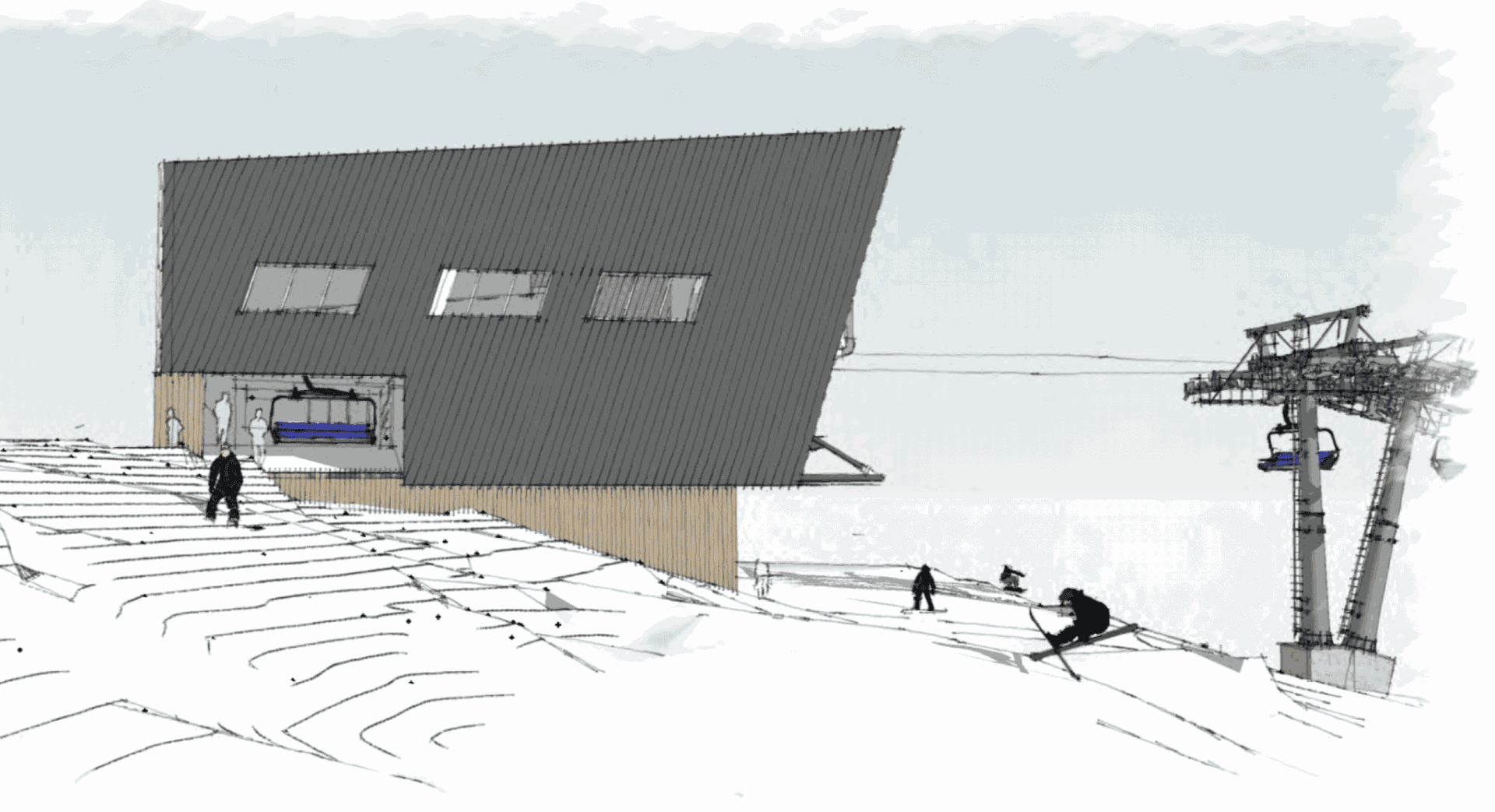

The Mount Perisher 6-Chair is anticipated to be ready for the 2025 Australian winter season. The new Doppelmayr chairlift will operate at a speed of 4.5 metres per second, cutting travel time up the mountain from 11 minutes for the Double-Chair and 10 minutes for the Triple-Chair to a mere 5 minutes 31 seconds, so basically halving the time. It will increase capacity on Mount Perisher by 60% and facilitate greater flow of guests around the mountain, increasing lift capacity in the Mount Perisher precinct by 22%.