Skiing has been around for centuries, and over the years, numerous technological advancements in ski construction have dramatically enhanced the skier experience. The evolution has been astounding from the early days of wooden skis and leather boots to today’s high-tech construction.

The change has been especially theatrical in the last few decades and it seems almost every ski on the market today can truly perform. If you were given an unbranded pair of almost any all-mountain ski and took it for a ride in varying conditions, you would be hard-pressed to ascertain the brand.

This seems to be happening because ski manufacturers are figuring out what works best and are becoming fairly homogeneous with construction. The materials, shapes, and profiles are looking more and more alike.

However, ski innovation is ever-changing and we can certainly expect to see even more exciting transformations in the future. From advanced materials to cutting-edge design and technology, what could the future bring? Just when you think the best technology is already out, we are blown away by the next big advancement. Sometimes just a small design tweak can have a big impact on performance.

Let’s take a look at how ski technology has changed over the years and what the next big thing, or things, will be in the future.

How Skis Have Changed in the Last Few Decades

It used to be when skiers would talk about “early rise” it meant waking up before the sun rose to catch the first chair. A lot has surely changed from the past when skis were long, straight, and skinny. Today there are a mind-blowing number of options for skiers to customize their style of riding. There are carving skis, powder skis, park skis, touring skis, and all mountain skis just to name a few.

Advances in technology, materials, and design have led to improved performance, safety, and comfort for skiers. These advancements have come under two main areas: shape and materials.

Sidecut and Rocker

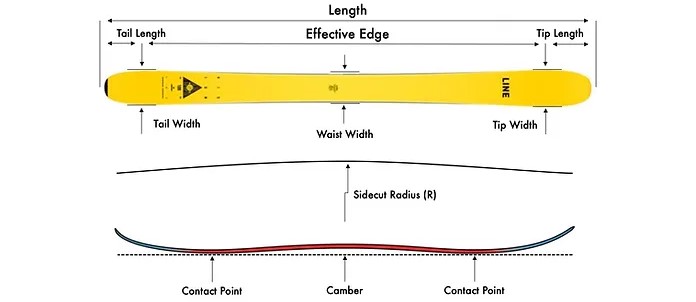

I remember when someone would tell me their skis were old and I would say, “Well, at least they are shaped.” Shape or sidecut refers to the difference in the width of the ski between the tips and the tails. When skis started being made with curved sides it created a whole new skiing experience. Changing the sidecut of the ski made it easier to initiate turns. The turn radius could also be customized with a long or short sidecut.

Rocker, or reverse camber, was the next big revolution. Rocker describes the amount of the ski that curves off the snow when the skis are lying flat. The more rocker a ski has the better it will float in deep snow.

Christian Avery is the Product Manager for Blizzard Technica in North America and he believes this is the most significant change we’ve seen in recent history. “Unequivocally shapes have been the biggest change in ski innovation in the past couple of decades,” he said. “Both in the footprint of the skis and also specifically in the rocker camber profile. Tuning different shapes to different snow conditions, tuning different shapes to performance levels to meet the needs of the category.”

The opposite of rocker is camber, which refers to the bow in the ski between the tips and the tails when the ski is lying flat. More camber will be your friend for charging hardpack snow. Skis are often made with both rocker and camber meaning they have the versatility to ski in all conditions.

Additionally, intermixed in this time came the “twin tip” design that had both the tips and the tails of the ski curved up. This allowed for skiing both forwards and backward (switch) and helped propel the freestyle movement. This style of riding is comprised of aerials, halfpipe, and slopestyle skiing where skiers ride a course consisting of rails, jumps, and other terrain park features.

Materials

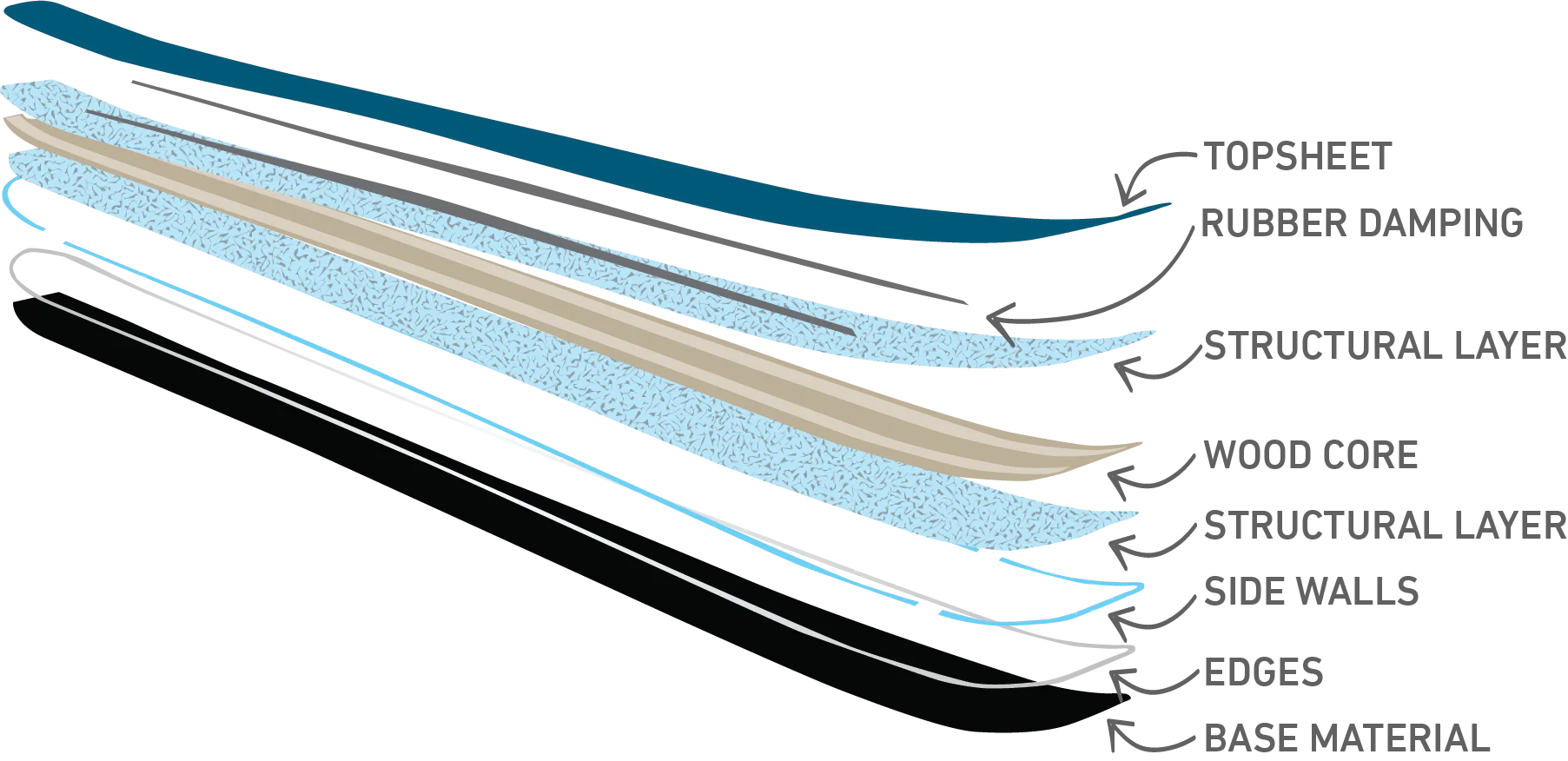

Another major area where skis have changed is the materials they are comprised of. Substances such as carbon fiber, metal, fiberglass, various kinds of wood, and other materials can have a substantial effect on the performance of the ski. Different materials have varying levels of weight, stiffness, durability, and flexibility.

The variety of materials creates a seemingly endless set of combinations that skis can be layered and constructed. This has further improved how they perform on the mountain as well as specializing the construction for certain preferences. From the light and playful to the heavy and hard-charging, it is a wonderful time to be alive for ski buyers.

What’s Next for Ski Innovation?

With all the advancements over the years and how good ski performance has gotten, it is logical to question what could come next. For a while skis kept getting lighter but at some point, you give up performance. That seems to be reigning in now.

Will the shape and rocker profiles continue to evolve? It may seem that every shape profile has already been produced, but Sam Kimmerle, who is the Brand Manager for 4FRNT, doesn’t necessarily think so.

“I think there is still a lot of room for innovation within the shape realm,” Kimmerle claimed. “That is something we (4FRNT) are hyper-focused on right now. For the last 12 years, we have been focused on the rocker scene and I think a lot of other companies are doing that as well.”

Avery isn’t so sure that shapes will continue to be the biggest change we see. “I wouldn’t say that every profile of ski has been done, but it’s pretty clear that looking at the competitive landscape that everyone is set on where home base is,” he declared. “Everyone is working from the same philosophy and then you see tip toes out if it’s a really crazy powder ski or an out-of-the-box carving ski.”

Peak Ski Company is a new player in ski manufacturing and they have credible momentum going for them with Bode Miller on board as a co-founder. On its website, they have a quote that says “Designed like no other ski to ski like no other ski.” It is safe to say they are not in the market to do what has already been done.

Andy Wirth is the co-founder of Peak Skis and he provided some insight into the company’s philosophy. “We have a truckload of respect and appreciation for the skis that we’ve been on, but we think there is something notably better that we can create,” he said. “There’s been a certain saneness to their creation and development and in some cases may be more based on marketing than true innovation. There’s room and opportunity for innovation and true development across the board.”

Undoubtedly, major ski manufacturers have significant research and development departments. Those companies are not going to want to give out trade secrets or intellectual property. Brands are doing tons of market research and finding out what skiers want. They are paying attention and reading online forums. The biggest changes to come will likely be consumer driven.

On this matter, Wirth said,

“I have some ideas of what the next big thing in ski construction could be but nothing specific because much like us, other companies tend to keep the things that you think are truly of interest and innovative in-house. There are some smart folks out there. The development process and the time from the development of prototypes to the development of skis is 18-24 months. They could be working on something that’s as innovative as heck, but we won’t see it until the 2024-25 season.”

Adding further, Kimmerle said, “It’s tough to say what the next big thing in ski innovation will be because we haven’t seen anything groundbreaking in 20 years or so. I think materials are an interesting one. For us, it’s just fine-tuning what we are currently doing to make skis that we think are already really great even better.”

Some of the industry experts did share some more specific insights into what the future could hold. More directly, Avery thinks that a binding that is integrated into the ski is a logical advancement that could be on the horizon.

“I think the near term in 3-5 years, the changes will be in the flex and shearing (the way the materials interact with each other),” he said. “In the longer term what needs to happen next is a different way to integrate the bindings into the skis. We have a fairly antiquated three-piece setup where people buy boots, bindings, and skis. Getting those three things to come together in a different way has a lot of potential. To unlock the next potential on the performance side of things is to find some standardization of how we integrate the bindings in the boot-to-ski connection. Binding integration will immediately have ramifications for the boots as well. You can imagine a ski boot that has the ability to articulate and flex with the ski as well.”

As you can see, the conclusion of what could be next for ski innovation is a bit murky but still exciting. We will likely continue to see changes in how the materials of skis are put together and how they interact and consequently how that affects the flex of the ski. We will also assuredly continue to see changes in shape and rocker to get even more specific performance results. Could an integrated binding and even integrated boots be in the future?

The next big thing or things for skis may still be top secret in the development stages of the ski brands. Whatever it is, skiers can certainly look forward to continued advancement and performance improvements in the future.